Heavy Equipment Safety

Heavy equipment safety is part of the job when working on construction sites, in mining operations or anywhere in between. Because using heavy equipment comes with significant risk, the Occupational Safety and Health Administration (OSHA) sets out required safety procedures to protect operators and surrounding workers.

Operators and managers need to comply with OSHA regulations and understand how to work safely around heavy equipment.

Pre-Operation Heavy Equipment Precautions

A few simple steps can set the tone for a safe and productive day. Here’s what you should do before approaching heavy machinery.

1. Inspect Equipment

Start every shift with a walkaround.

Here’s what operators should check:

- Tires and tracks: Look for signs of wear, cuts or debris buildup.

- Hydraulics: Check hoses for leaks, cracks and signs of wear.

- Fluids: Top off or replace engine oil, coolant, hydraulic fluid and fuel.

- Lights, alarms and horn: Make sure everything is working.

- Controls, steering and brakes: Run a brief function check.

2. Assess the Jobsite

Jobsite assessments help identify risks related to the surroundings. Site checks should evolve with the job as materials shift, weather changes or crews rotate. Encourage team leaders to keep this top of mind and share observations during toolbox talks or shift handovers.

Assess the following during jobsite inspections:

- Terrain and ground stability: Identify soft spots, steep slopes or loose material.

- Overhead and underground hazards: Be aware of power lines, tree branches and underground utilities.

- Traffic patterns: Set clear paths for equipment and personnel to avoid crossing foot and machine traffic.

- Blind spots and visibility zones: Map out line-of-sight issues, and use spotters or mirrors.

3. Wear Personal Protective Equipment (PPE)

PPE protects against major accidents and smaller hazards like flying debris or loud engine noise. Standard protective gear for heavy equipment operations includes:

- Hard hat

- Respirators

- Work gloves

- Safety glasses

- Hearing protection

- Steel-toe shoes or boots

- High-visibility vest or jacket

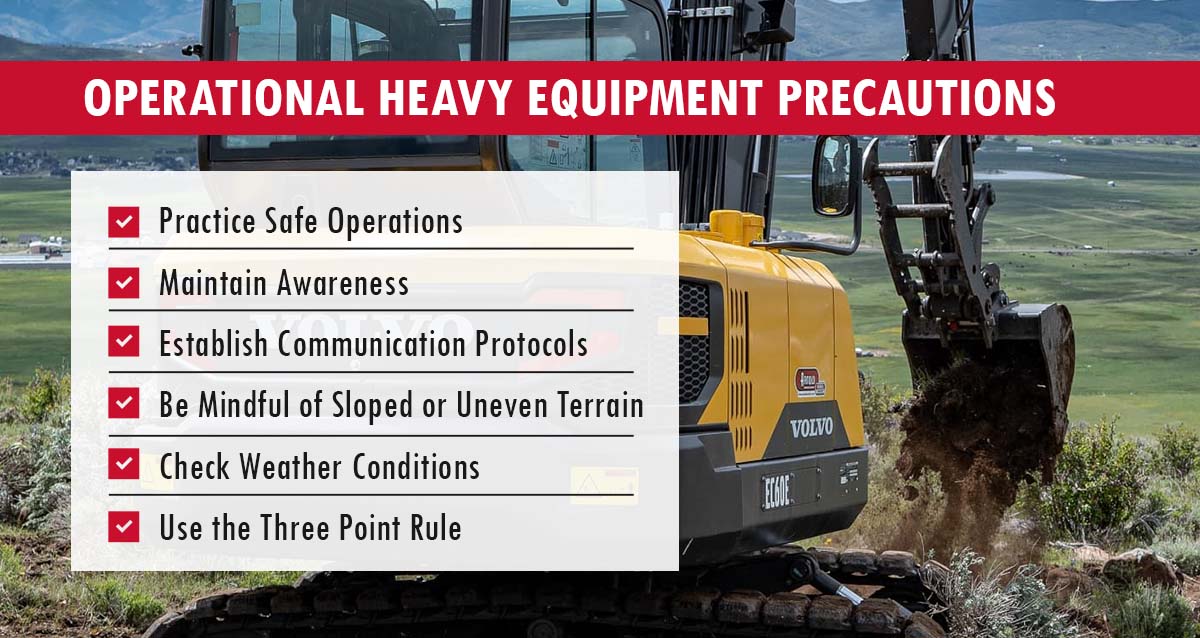

Operational Heavy Equipment Precautions

Heavy equipment operator safety becomes prevalent when the machine is in use. The following precautions can help your team work efficiently.

1. Practice Safe Operations

Operating heavy-duty equipment safely involves adhering to some basics to reduce the likelihood of incidents.

Working around heavy equipment safely involves:

- Always wearing a seat belt

- Using equipment only for its intended purpose

- Following the manufacturer’s operating manual, including weight limits and proper controls

- Keeping loads low and balanced when moving

- Avoiding sudden starts, stops or turns

- Locking the attachments before use

2. Maintain Awareness

Using a machine means constantly reading the environment and staying alert to subtle changes.

Operators should monitor:

- People nearby: Know where ground crews and other operators are.

- Blind spots: Use mirrors, cameras and spotters.

- Equipment behavior: Pay attention to unusual sounds, changes in resistance or fluid leaks.

- Terrain and obstacles: Stay mindful of slopes, drop-offs, trenches, loose fill and shifting materials.

3. Establish Communication Protocols

A well-coordinated crew works best when everyone knows what to expect and how to respond. Communication between operators and ground crews should be clear, consistent and suited to the environment.

Establish systems like:

- Hand signals: Have standardized signals to reduce confusion.

- Two-way radios: Radios are ideal for larger jobsites or when visual contact isn’t possible.

- Job briefings or pre-shift meetings: Holding quick huddles each day helps clarify tasks, hazards and who’s working where.

4. Be Mindful of Sloped or Uneven Terrain

Equipment behaves differently when weight shifts or traction is uneven. Best practices include:

- Avoid driving sideways to reduce rollover risk.

- Use low gear to maintain control on inclines or declines.

- Avoid abrupt stops or turns.

- Use stabilizers when stationary or operating attachments.

5. Check Weather Conditions

Wet, icy or windy conditions can change how machines perform.

Here are safety tips for heavy equipment operators:

- Reduce speed during rain or snow.

- Watch for reduced traction or visibility.

- Clear ice, snow or mud from steps, mirrors and windows before starting.

- Postpone operations if conditions pose safety risks.

6. Use the Three Point Rule

Some equipment-related injuries occur when getting in or out of the cab. Applying the three-point rule — always keep three points of contact with the machine — is an easy way to prevent these risks.

Post-Operation Heavy Equipment Precautions

The way equipment is shut down, cleaned and maintained determines its future reliability. Follow these post-operation steps to protect your machines and team.

1. Park and Secure Equipment

Park and secure equipment properly to prevent unintended movement, tampering and environmental damage.

Operators should:

- Park on level, stable ground.

- Lower all attachments to the ground.

- Set the parking brake and shut down the engine.

- Remove the key and lock the cab to prevent unauthorized use.

If parking on a slope is unavoidable, use wheel chocks. They protect the machine and keep the site safe for everyone moving around the area.

2. Report Issues

If anything felt off during the operation, report it right away. It’s much easier to fix something early than after it becomes a serious failure.

Encourage operators to:

- Speak up even when the problem seems minor.

- Log issues immediately using the system your site uses.

- Describe when the issue occurred, how it affected performance and any visible signs.

3. Clean the Machine

Cleaning is critical to equipment care because it reduces wear and prevents buildup that can damage moving parts.

After each use:

- Wipe down windows, mirrors and lights.

- Inspect surfaces for cracks, leaks or wear.

- Clean off grease points and exposed moving parts.

- Clear mud and debris from tracks, tires and undercarriages.

4. Maintain Heavy Equipment

Scheduled maintenance by an experienced service provider should follow the manufacturer’s service intervals. However, basic post-operation upkeep helps prevent unexpected issues.

Mining or construction equipment safety upkeep tasks include:

- Inspecting filters and belt: Look for blockages, fraying or wear.

- Checking fluid levels: Top off engine oil, coolant and hydraulic fluids.

- Monitoring wear parts: Track the condition of tires, cutting edges or teeth and replace them as needed.

- Reviewing telematics or diagnostic alerts: Use built-in monitoring tools to identify system warnings or unusual performance data.

5. Follow Proper Lockout Tagout Practices

Lockout tagout is an important precaution that prevents machines from powering up while being serviced or inspected.

Here’s what it involves:

- Preparation: Authorized and trained personnel should check for all types of hazardous energy.

- Shut down: Turn off the machine completely.

- Isolation: Isolate the machine from power sources, including the engine, battery and hydraulics.

- Lock: Place a lock on the control panel or ignition switch.

- Tag: Attach a tag showing who applied the lock and why the equipment is out of service.

- Check for stored energy: Double-check that there isn’t any residual energy. If so, relieve it.

- Remove the lock: Only the person who applied the lock should remove it after confirming the equipment is safe to use again.

Emergency Procedures

Clear emergency procedures reduce confusion and minimize harm. Here are some heavy equipment safety tips for when issues arise.

Responding to Equipment Malfunctions

When equipment doesn’t perform as expected, the priority is to halt operations and assess the situation.

Operators should:

- Stop the machine immediately.

- Secure the equipment by lowering attachments, engaging the parking brakes and shutting down the engine.

- Warn others nearby using radios or signals.

- Report the issue to a supervisor or the maintenance team.

- Do not attempt field repairs unless trained and authorized to do so.

Dealing With Accidents and Injuries

In the event of an injury or collision, focus on keeping people safe and reaching for the right support.

Basic steps include:

- Call for help immediately by using the site’s emergency communication system.

- If trained to do so, administer first aid while waiting for professional responders.

- Secure the area by moving other equipment away and restricting traffic.

- Take a record of what happened, who was involved and the contributing factors.

Partner With Arnold Machinery Company for Reliable Heavy Equipment

Arnold Machinery Company has over 95 years of experience helping businesses in construction, mining and material handling find equipment solutions they can count on.

We help you choose the right used or new equipment and keep your fleet running with exceptional customer service. Our team can walk you through the latest technologies to streamline operations. We also offer a range of parts and services.

Our Silver Service® guarantee is our promise to do everything possible to satisfy you.

Get in touch with us today to learn more.